Enhancing Durability and Aesthetic Appeal with Concrete Protective Coatings

Concrete is one of the most popular and versatile building materials in Australia, celebrated for its strength and durability. Yet, even the sturdiest concrete is vulnerable to the harsh challenges posed by time and nature. In Sydney—a city that experiences a mix of intense UV exposure, coastal salt air, and occasional heavy downpours—the need to protect concrete surfaces is paramount. Concrete protective coatings offer an effective solution by not only enhancing the lifespan of these surfaces, but also improving their appearance and safety.

Understanding Concrete Protective Coatings

Concrete protective coatings are specialised materials that form a robust, bonded layer over concrete surfaces. Their primary purpose is to shield the underlying concrete from various forms of deterioration—whether that be chemical spills, abrasion, moisture penetration, or UV damage. When applied correctly, these coatings create a barrier that significantly reduces wear and tear while also adding an attractive finish to the surface.

The benefits of protective coating for Sydney property owners and contractors extend beyond mere protection. For many it lies in their ability to transform a basic concrete surface into one that is easier to clean, more resistant to stains, and far less prone to degradation. In a bustling urban environment where every structure faces environmental stress, protective coatings are a wise investment, providing peace of mind and long-term cost savings.

Types of Concrete Protective Coatings

There is a range of concrete protective coatings available in the market, each designed to address specific challenges. The choice of coating largely depends on the intended use of the surface and the environmental conditions it will face.

Epoxy Coatings

Epoxy coatings are among the most popular options, especially in industrial and commercial settings. They offer excellent adhesion, chemical resistance, and durability. Their glossy finish is highly attractive, and the sealed surface is easier to clean, which makes it ideal for busy areas. However, one drawback to be aware of is that epoxy can be sensitive to prolonged UV exposure, often leading to yellowing if not protected adequately.

Polyurethane Coatings

For areas that experience heavy foot or vehicle traffic, polyurethane coatings are a preferred choice. These coatings are known for their exceptional resistance to abrasion and a wide range of chemicals. Their flexibility allows them to withstand Sydney’s temperature fluctuations, making them particularly suitable for outdoor applications. Available in both high-gloss and matte finishes, polyurethane coatings can be tailored to match aesthetic requirements without compromising on performance.

Acrylic Coatings

Acrylic coatings are celebrated for their quick-drying properties and ease of application. They offer solid resistance against UV rays, which is a significant advantage in Sydney’s sun-drenched environment. Although they may not match the chemical resistance of epoxy or polyurethane options, their affordability and straightforward maintenance regime make them popular for residential projects and areas where heavy industrial traffic is not a concern.

Polyaspartic Coatings

A newer entrant to the market, polyaspartic coatings combine many of the best features of both epoxy and polyurethane. They cure rapidly, provide excellent UV stability and are highly durable, making them a top choice in commercial settings where minimising downtime is critical. Their versatility and enhanced performance are gradually winning over many Sydney contractors looking for reliable, high-performance protective solutions.

Why Sydney Demands Superior Protection

Sydney’s distinctive climate and urban environment present a unique set of challenges for concrete surfaces. The region’s intense sunlight can cause significant thermal stress, leading to cracks and surface degradation over time. In coastal areas, the salt in the air acts as a corrosive agent, accelerating wear on unprotected concrete. Moreover, the occasional heavy rain and the inevitable cycle of freeze-thaw in shaded pockets add further strain.

Protective coatings play a critical role in mitigating these risks:

- Enhanced Durability: By creating a robust barrier, these coatings protect against mechanical wear, chemical spills and environmental pollutants, thus extending the service life of concrete surfaces.

- Improved Safety: Many coatings are designed with slip-resistant properties, which is particularly important for public walkways, driveways, and commercial areas where safety is paramount.

- Aesthetic Versatility: Available in a variety of finishes and colours, coatings can transform a dull concrete slab into an appealing surface that complements modern architectural designs.

- Cost-Effectiveness: Although the initial cost of application might be higher than leaving the concrete untreated, the reduction in maintenance and repair expenses over time makes protective coatings a sound financial decision.

- Environmental Resistance: High-quality coatings are formulated to withstand UV degradation, moisture penetration, and even aggressive chemicals, ensuring that the protective benefits endure even under Sydney’s variable conditions.

- Ease of Maintenance: Sealed surfaces resist staining and are easier to clean, reducing the need for harsh cleaning agents that could otherwise damage the concrete.

The Application Process: Key to Long-Lasting Results

Achieving the best performance from a concrete protective coating starts with meticulous surface preparation. The concrete must be clean, dry, and free of any contaminants such as oil, dust, or previous coatings. This preparation is vital because even the most advanced coating will fail to adhere properly if the underlying surface is compromised.

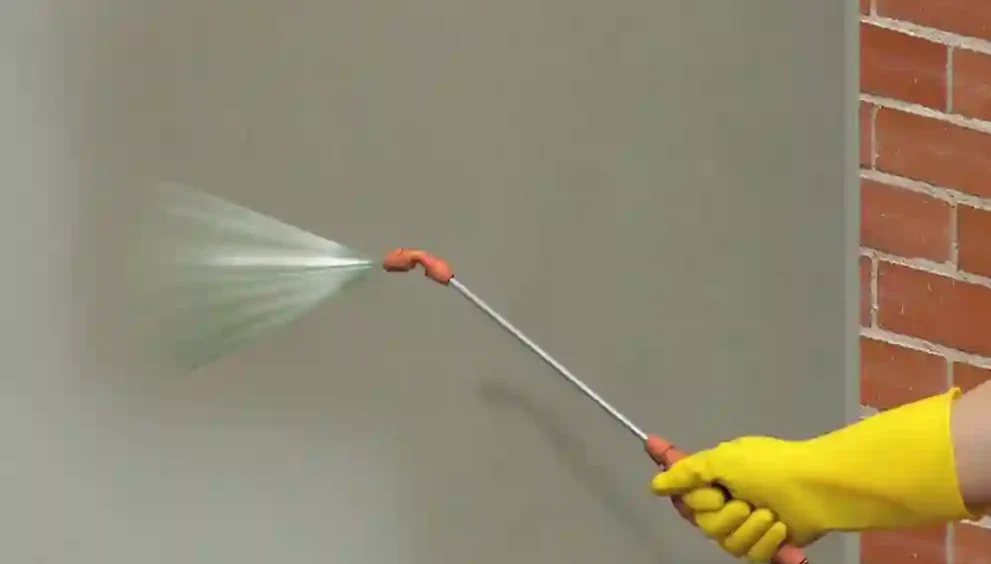

Once the surface is ready, the coating can be applied through various methods, including brushing, rolling, or spraying. The chosen method often depends on the scale of the project and the type of coating being used. For instance, large commercial facilities may benefit from a spray application to ensure an even and efficient spread, while smaller residential projects might be more suited to the control offered by a roller or brush.

Environmental conditions during application are another crucial factor. Most coatings require specific temperature and humidity levels to cure effectively. In Sydney, where weather patterns can be unpredictable, professionals typically plan the application for periods of stable weather to avoid issues like premature drying or incomplete curing. Following the manufacturer’s guidelines during this stage is essential for ensuring that the protective layer performs as expected over its lifespan.

Navigating Local Regulations and Industry Standards

In Sydney, as across Australia, the use of protective coatings is subject to strict regulations and industry standards. These measures are in place to ensure that the products used are safe, effective, and environmentally sound. Local councils and state authorities may have specific requirements, particularly for coatings applied in public spaces or commercial developments.

Contractors working in Sydney are expected to be conversant with these regulations and often collaborate with suppliers who provide coatings that meet or exceed these standards. This diligence not only guarantees that the installation is compliant with local laws but also reinforces the quality and durability of the finished product. Property owners can thus be confident that their investment is protected by a product that is both industry-approved and suited to the local environment.

Innovations and Trends in Sydney’s Market

The market for concrete protective coatings in Sydney is dynamic, with constant innovations driven by advances in material science and environmental awareness. Recent developments have seen the introduction of coatings that are not only more durable but also environmentally friendly. Many modern formulations boast reduced levels of volatile organic compounds (VOCs), contributing to healthier indoor air quality and a lower environmental footprint during application.

Local suppliers and contractors are quick to adopt these innovations. Investment in training and certification programmes ensures that the latest techniques and products are being used, allowing Sydney to stay at the forefront of protective coating technology. This commitment to quality and sustainability is making a noticeable difference in how concrete surfaces are maintained and preserved across the city.

Maintaining Your Coated Concrete for Longevity

While a high-quality protective coating can dramatically improve the durability and appearance of concrete surfaces, regular maintenance is still essential. Routine inspections can help spot any areas where the coating has begun to wear or where minor repairs might be needed. Addressing these issues promptly can prevent further damage and extend the lifespan of the coating.

For best results, property owners should adhere to the cleaning guidelines provided by the manufacturer. Typically, this means using gentle cleaning agents and avoiding abrasive methods that could scratch or wear away the coating. By scheduling periodic maintenance and cleaning, the protective benefits can be preserved for many years, ensuring that the investment continues to pay dividends in both performance and appearance.

Enhance Durability and Protect Assets

Concrete protective coatings are an invaluable asset for anyone looking to enhance the durability, safety, and aesthetic appeal of concrete surfaces in Sydney. With a wide array of products—from epoxy and polyurethane to acrylic and polyaspartic coatings—there is a solution tailored to meet the diverse needs of Sydney’s residential, commercial, and industrial sectors.

In a city where the elements can be as challenging as they are beautiful, investing in the right protective coating is a strategic move. It not only protects your property against the relentless wear and tear of urban life but also contributes to a more attractive, safer, and ultimately more cost-effective structure. As technology continues to advance and environmental considerations become ever more significant, Sydney’s concrete surfaces are being equipped with coatings that set new standards in performance and sustainability.

For homeowners, commercial developers, and public agencies alike, the time is ripe to consider the benefits of concrete protective coatings. By understanding the different types available, the importance of proper application and maintenance, and the strict local standards that govern their use, property owners can make informed decisions that ensure long-term durability and aesthetic excellence.

Investing in a quality protective coating today means fewer repairs, reduced maintenance costs, and a lasting improvement in the visual appeal and safety of your concrete surfaces. With Sydney’s diverse climate and urban challenges, protective coatings offer a robust solution that stands the test of time—ensuring that your investment remains as resilient and attractive as the city itself.

Concrete, in its raw form, has served Sydney well over the decades, but it is the innovation in protective coatings that is paving the way for a new era of longevity and style. By embracing these modern solutions, Sydney is not only safeguarding its infrastructure, but also enhancing the overall quality of its built environment for future generations.

Whether you’re upgrading a family driveway, refurbishing a commercial space, or planning a major public infrastructure project, concrete protective coatings offer the ultimate blend of durability, functionality, and visual appeal. Embrace the future of construction and maintenance in Sydney—where quality, sustainability, and performance meet in one robust, protective layer.